Wood Chips For Fuel/Biomass

You are here:

- Home

- Our Products

- Wood Chips For Fuel/Biomass

WOOD CHIPS FOR FUEL

The Future of Sustainable Industrial Heating

Fuel wood chips are chips produced as a byproduct of logging, wood processing, or specifically manufactured for energy production. These chips are commonly used as a renewable energy source for heating and electricity generation. They are typically derived from a variety of wood types, including hardwood and softwood, and may vary in size, moisture content, and density. Fuel wood chips are often used in biomass boilers or industrial furnaces due to their efficient combustion properties. They are considered a cleaner, more sustainable alternative to fossil fuels, offering a carbon-neutral energy source when managed sustainably.

There are many sources of wood that can be processed into woodchip fuel and there are equally as many ways in which the wood can be harvested, processed, loaded, transported, and received—all of which can impact the overall quality of the woodchip as a fuel. Important characteristics of wood fuel are energy content; moisture content; chip shape, size, and uniformity; ash content; and the presence of dirt and other debris. (For definitions of each of these terms, please see the glossary at the end of this document.) TYPES. There are four main types of woodchip fuel: paper chips, bole chips, whole-tree chips, and urban-derived wood fuel, in order from highest to lowest quality. Each differs on important characteristics like ash content, uniformity, and the absence of dirt and debris.

Outlined here are the technical specifics for four main woodchip heating fuel sources labeled Grades A through D in order of quality:

Grade A. Paper-grade chip (high quality)

Grade B. Bole chip (medium quality)

Grade C. Whole-tree chips (low quality)

Grade D. Urban-derived wood fuel (lowest quality)

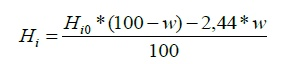

Theoretical calculation of caloric value

To calculate the caloric value (MJ per kg) of wood with specific water content (M %) the following formula can be used:

During seasoning, the 10 percent decrease in moisture entails an approximate 0.6 kWh per kg (2.16 MJ per kg) increase in energy content.

For practical purposes the following average values are used for wood fuels:

NCV0 = 18.5 MJ/kg = 5.14 kWh/kg OVEN-DRY WOOD (M 0%)

NCV10 = 17.0 MJ/kg = 4.7 kWh/kg PELLETS (M 10%)

NCV20 = 14.4 MJ/kg = 4.0 kWh/kg FIREWOOD (M 20%)

NCV30 = 12.2 MJ/kg = 3.4 kWh/kg WOOD CHIPS (M 30%)

We supply wood chip of the desired specification and moisture content to biomass boilers of all sizes from 15kW to 10MW and more. All of our timber is FSC certified and sourced from locally managed woodlands, supplied as round wood to our distribution hubs where it is air dried and then chipped.

Product Categories

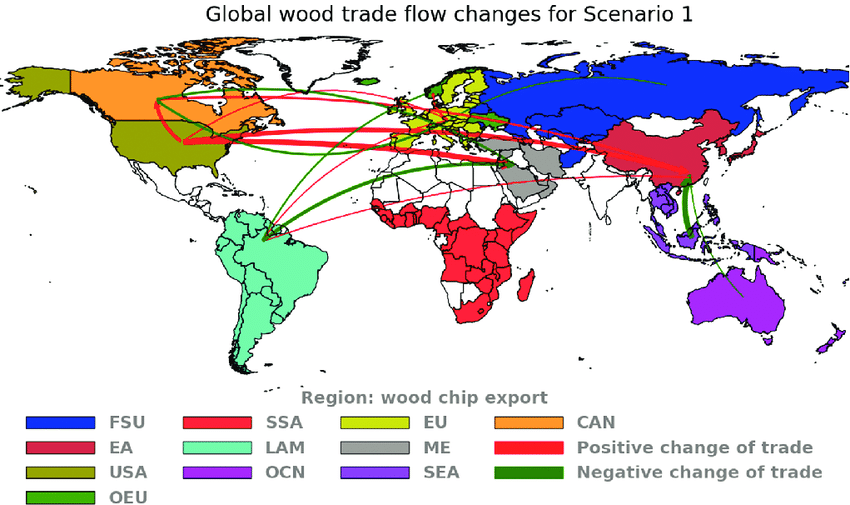

Products Trade Flow

Product tags